Things to Consider for Protective Coating on Thermocouple Sheaths

Published on July 02, 2021

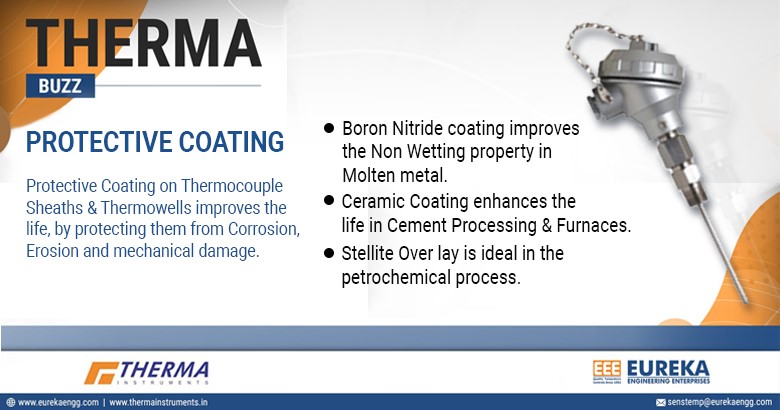

The outer sheath of thermocouples is instrumental in protecting the temperature sensors from external force and damage that are mostly a consequence of corrosion, hustling, anomalous high temperature and erosion. Coating on the thermocouple sheaths shield them from chemical corrosion and mechanism corrosion damages. The coatings are available in Glass Enamel, Ceramic, Stellite, Boron Nitride and Tungsten Carbide.

Things to Consider for Thermocouple Sheath Coat:

- Molten Nonferrous metals require coating materials with excellent non-wetting proper

- For using in Molting Aluminium, apply Boron Nitride Coating over Stainless Steel

- Opt for special Ceramic Coating for increasing the lifespan of sheaths that are used in cement processing kilns, diverse furnace applications and pre-heaters

- Confirm if Stellite-Weld Overlay coating is applied on Thermowells used in Ethane, Cracking Furnace for Propane, High Velocity environments like power stations and such applications. The coating promises a longer lifespan. Stellite weld overlay Thermowells last longer than regular Thermowells and are utilised for toughness and immunity to high-temperature erosion.

Eureka Engineering promises on-time delivery of customised products manufactured using avant-garde technology. Certified ISO 9001-2015 Eureka Engineering has a versatile product portfolio and deals in Thermocouple Assemblies, Thermowells, Digital Gauges for application in Plastics, Foundries, Smelters, etc.

Our well-stocked inventory of cables and accessories reaches to a wide network of customers spanning across the country.

Know more about our product range at https://www.eurekaengg.com

Have Any Questions on temperature sensing and control systems

Ask Our Experts!

Recent Posts

Looking for high-grade Temperature Sensors and Thermocouples for Aluminum Smelters?

Looking for the Best Temperature Measurement Solutions for Your Cement Plant? Eureka Has Got You Covered!

Things to Remember for Selecting Right Thermocouple Sheath Material for Molten Metal

Things to Consider for Protective Coating on Thermocouple Sheaths

Things to remember for Choosing Thermocouple Connectors

Things to Remember while installing Thermocouples and RTDs with Compression Fitting

Ever Wondered How Thermocouple Works

Five Mistakes to Avoid when Using a Thermocouple

Five Hacks of using Thermocouple at your shop floor

All Rights Reserved © EUREKA ENGINEERING ENTERPRISES - 2019

Engineered by The Impals